PLC Control System Nespresso Coffee Capsule

Filling And Sealing Rotary Machine

Introdution of the Nespresso coffee capsule filling and sealing

rotary machine

This nespresso coffee capsule filling and sealing rotary machine

can be equipped with individual process modules for a wide range of

applications. It can handle both injecting and thermoforming

function. It is suitable to fill in liquid, powder and granule

materials, such as coffee powder, milk powder, tea, yogurt and

other materials.

It can be used for Compatible Nespresso capsules, Lavazza blue or

point, Pod, K-cup, Kshot and so on. You can change the mould for

your need.

Parameters of the Nespresso coffee capsule filling and sealing

rotary machine

| Filling weight range | 0-6g (customized) |

| Filling accuracy | ±0.15g |

| Residual oxygen | <1% |

| Max speed | 3000 BPH |

| Hopper capacity | 1.0L-2.5L / 110L |

| Control system | PLC ( OMRON, SCHNEIDER, ROCKWELL ) |

| Displayer | 7 inch touchscreen |

| Power supply | AC 110V, 220V, 380V 50-60Hz |

| Air supply | 6 BAR |

| Shape | rotary |

| Warranty | one year |

| Coffee capsule materials | PP, Aluminum, Biodegradable |

| Dimension | 1745(L)x1150(W)x2385(H) |

Characters of the Nespresso coffee capsule filling and sealing

rotary machine

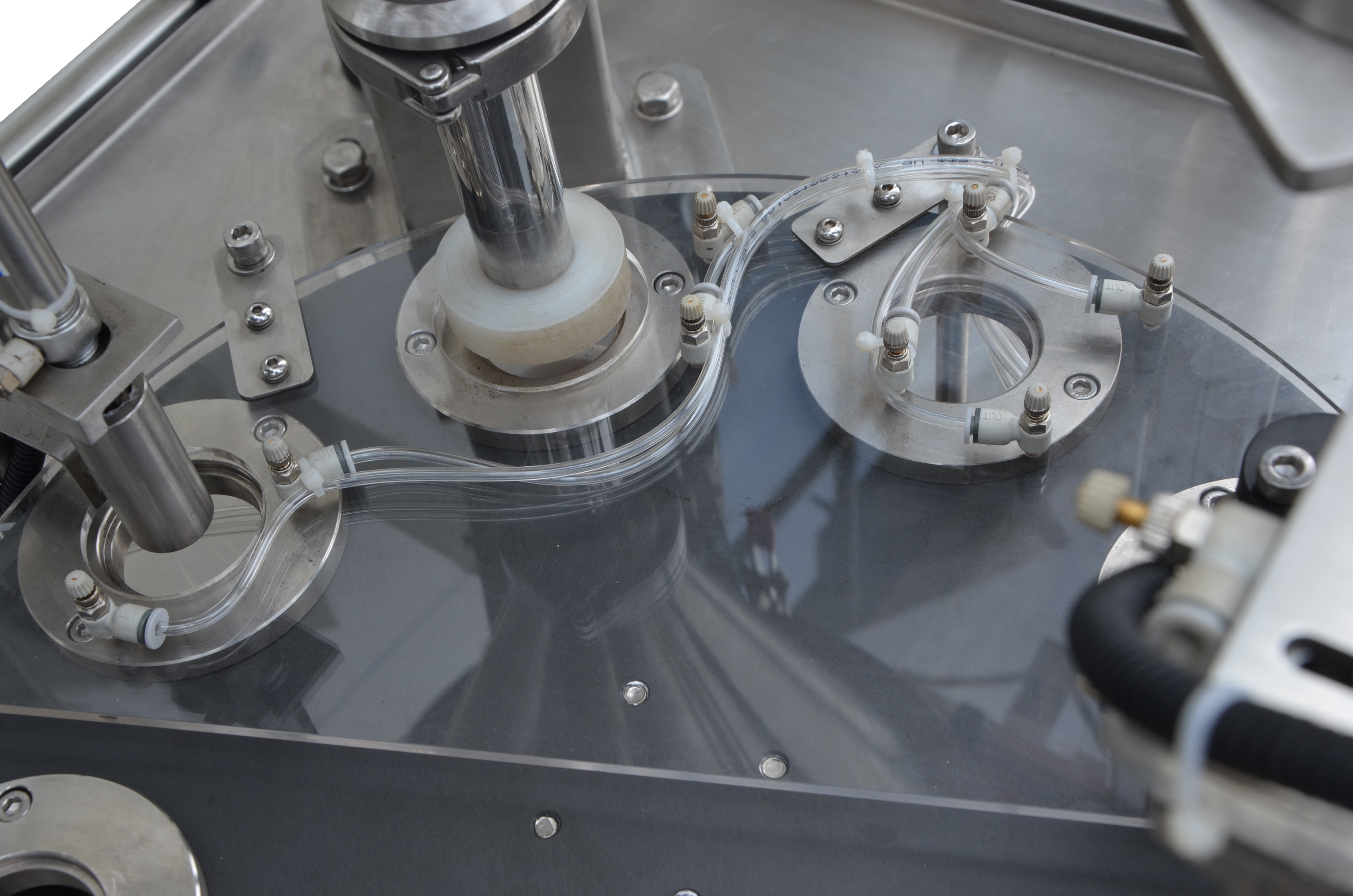

•The whole machine adopts stainless steel materials;

•It adopts high precision of the chain wheel, gearbox, bearing and

dividing box which determine the fast, stable and accurate

operation of the machine to prolong the service lifetime and the

pleasant rhythm.

•The high-quality pneumatic components make the air circuit of the

machine run stably. The stable air pressure and the even air flow

inside the machine greatly avoid the failure, namely can greatly

improve the production capacity and guarantee the service lifetime

of the machine;

• Electrical parts are from most famous brands with best quality

(Schneider, Siemens, Allen-Bradley…)

• UV sterilization system provides a good production environment

for capsule production;

•Electromagnetic storm has largely solved the problem of static

electricity in the process of powder packaging, resulting in the

failure of packaging process;

•The peristaltic pump drop filling device is ready for adding

liquid flavors into the capsule in the future;

•The second strengthen heat sealing. It eliminates the risk of

defective products entering the market, even if the first heat seal

fails;

•The online weighing device feeds the data back to the PLC in real

time, identifing the unqualified products and automatically injects

them;

•Discharging over-turning device prepares for the following

packaging of the capsule, bagging or cartoning;

•Automatically counts the output of the finished capsules;

•Roll film cutting and sealing system with high-precision fine

tooth cylinder blade can realize online cutting and sealing at the

same time. The sealing deviation is within 0.1mm. With the

identification mark system, servo motor drives roll film expansion

and dragging precisely;

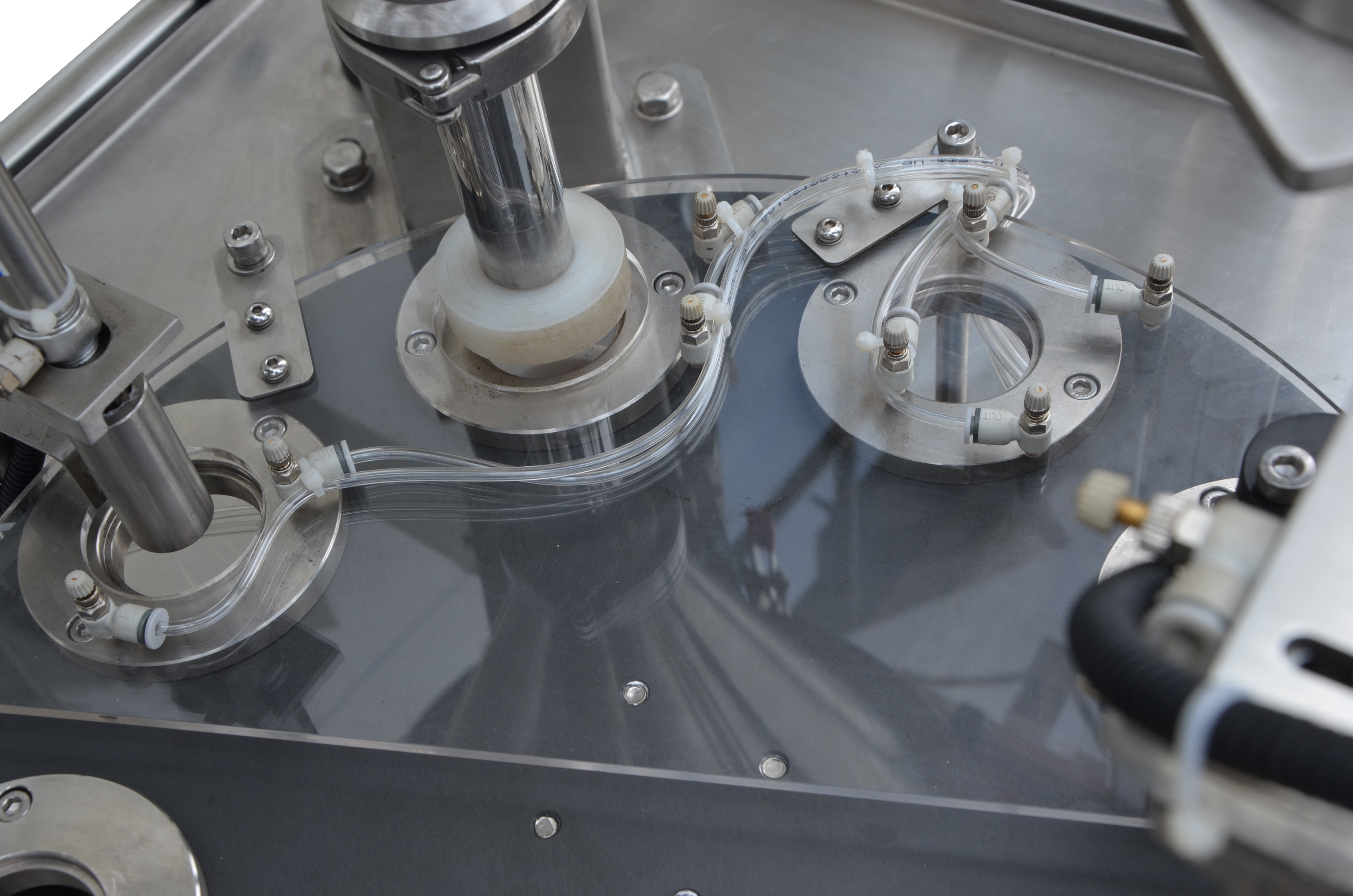

• With nitrogen filling device, it creates a low-pressure

environment. When the nitrogen source pressure and flow rate meet

the conditions, the residual of Oxygen will be reduced to less than

1% in the capsule, so that the fresh coffee is sealed and wrapped

by highly pure nitrogen;

•The remote control system, to a great extent, solves the problem

of international PLC and HMI inconsistency of the software

installed on the PC side. Moreover, the customer can observe the

condition of the parameter value of the machine, the failure rate

of the machine, the production efficiency and so on in real time

every day through the mobile app;

•Screw feeder and vacuum feeder, according to the choice of

customers to configure the corresponding automatic replenishment

system.

Usages of the Nespresso coffee capsule filling and sealing rotary machine

1. cups loading

Vibrating sorter or centrifugal sorter can help you to feed the

capsules automatically.

2. auger filling

Vacuum feeding machine or screw feeding machine or elevator machine

automatically send materials. It is of easiness and convenience.

3. nitrogen flushing

It creates a low-pressure environment. When the nitrogen source

pressure and flow rate meet the conditions, the residual of Oxygen

will be reduced to less than 1% in the capsule, so that the fresh

coffee is sealed and wrapped by highly pure nitrogen.

4. roll films

Cutting and sealing PP multi-layer compound film to close capsule's

top, if the film with an eyemark, it can cut film and make sure

that the logo is on the capsule's center. Cutting and sealing in

one step will realize lids to close capsule's top precisely.

Positiong lid in the center of capsule top. In the long time, it

will save film package cost.

5. heat sealing

Heat sealing or ultrasonic sealing, you can choose flat sealing or

line sealing. Different kinds of sealing to make the package more

appealing.

6. cups output

Automatically count finished capsules' quantity. It has an online

weigher check function helping reject unqualified products by

itself.

Container specifications

| Materials | Filling weight | Lifetime |

| PP | 0-5.5g

| 6 months |

| PBT | 12 months |

| PP with EVOH | 18months |

| Aluminum | 0-6g | 36 months |

| Biodegradable | 3 months |

All above have the same diameter (37mm) and sealing film (aluminum

foil).