Rotary Type Nespresso Coffee Capsule Filling Sealing Machine

With Less Than 1% Oxygen Remained

Introdution of the Nespresso coffee capsule filling and sealing

rotary machine

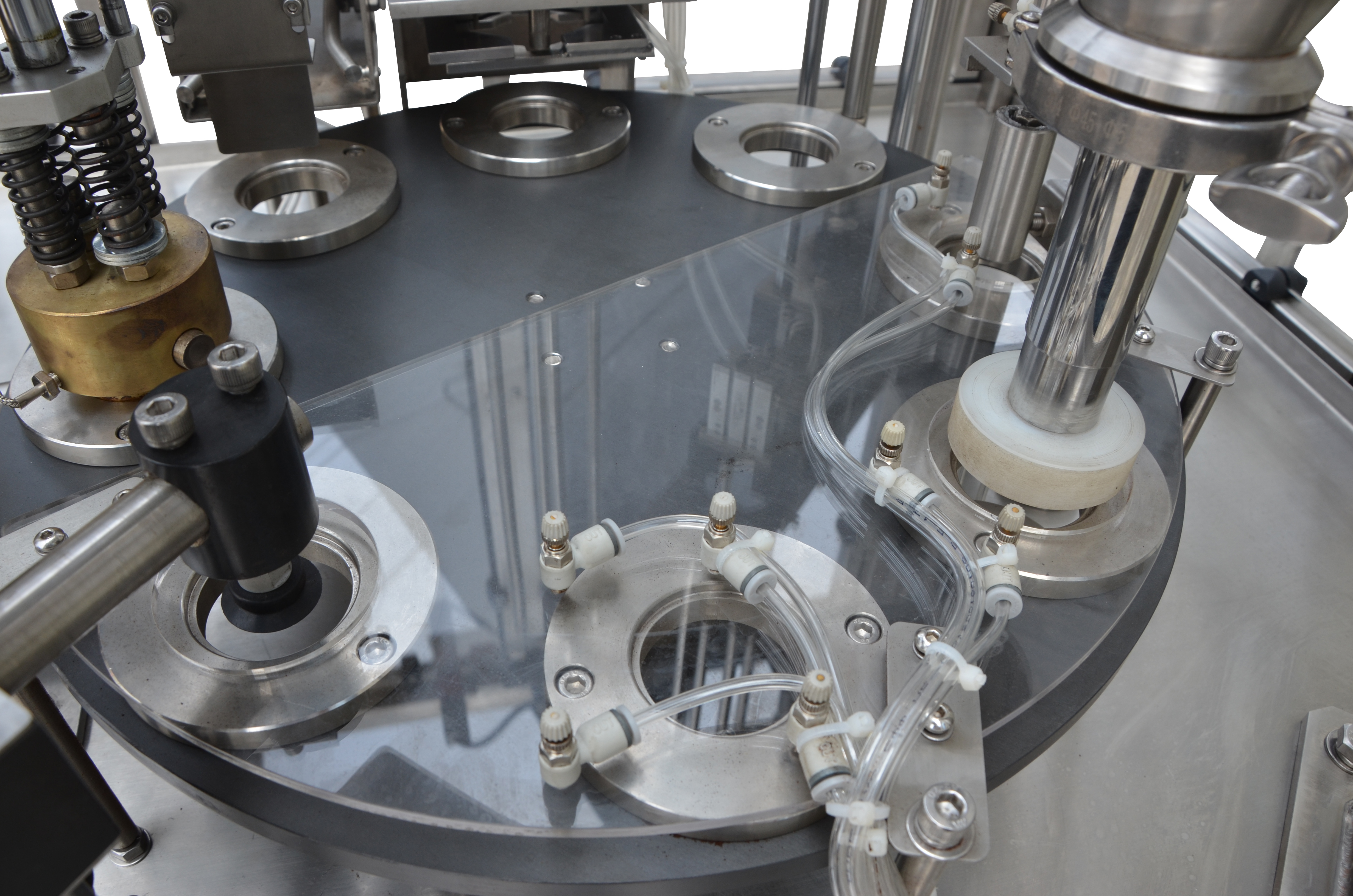

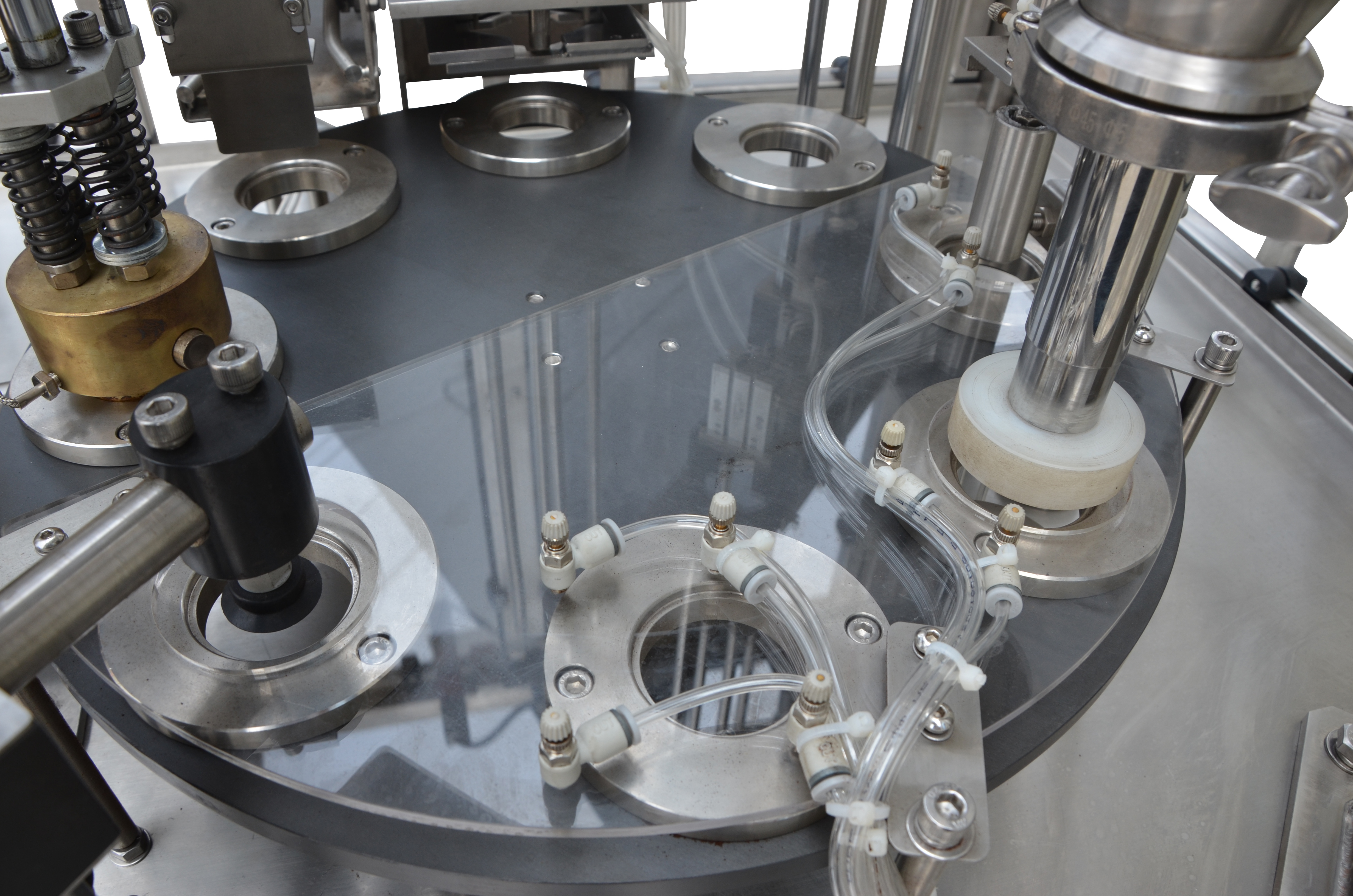

This nespresso coffee capsule filling and sealing rotary machine

can be equipped with individual process modules for a wide range of

applications. It can handle both injecting and thermoforming

function. It is suitable to fill in liquid, powder and granule

materials, such as coffee powder, milk powder, tea, yogurt and other materials.

It can be used for Compatible Nespresso capsules, Lavazza blue or point, Pod, K-cup, Kshot and so on. You can change the mould for your need.

Parameters of the Nespresso coffee capsule filling and sealing

rotary machine

| Filling weight range | 0-6g (customized) |

| Filling accuracy | ±0.15g |

| Residual oxygen | <1% |

| Max speed | 3000 BPH |

| Hopper capacity | 1.0L-2.5L / 110L |

| Control system | PLC ( OMRON, SCHNEIDER, ROCKWELL ) |

| Displayer | 7 inch touchscreen |

| Power supply | AC 110V, 220V, 380V 50-60Hz |

| Air supply | 6 BAR |

| Shape | rotary |

| Warranty | one year |

| Coffee capsule materials | PP, Aluminum, Biodegradable |

| Dimension | 1745(L)x1150(W)x2385(H) |

Characters of the Nespresso coffee capsule filling and sealing

rotary machine

Touch screen Omoron brand

Capsule loading: each line(hole) can hold 300 nespresso empty capsules

Omorn detect: no capsules no filling and sealing for the nespresso coffee

capsule filling sealing rotary machine

filling: Schneider Cylinder drive servo auger filling, accurancy can be

±0.15g

Sealing: copper sealing head, sealing is 100% perfect

Output: suck or catch, can add the conveyor sutomatic to come out

Usages of the Nespresso coffee capsule filling and sealing rotary machine

1. cups loading

Vibrating sorter or centrifugal sorter can help you to feed the

capsules automatically.

2. auger filling

Vacuum feeding machine or screw feeding machine or elevator machine

automatically send materials. It is of easiness and convenience.

3. nitrogen flushing

It creates a low-pressure environment. When the nitrogen source

pressure and flow rate meet the conditions, the residual of Oxygen

will be reduced to less than 1% in the capsule, so that the fresh

coffee is sealed and wrapped by highly pure nitrogen.

4. lids station

Two kinds of films you can choose. One is the precutting film, the

other is roll film.

5. heat sealing

Heat sealing or ultrasonic sealing, you can choose flat sealing or

line sealing. Different kinds of sealing to make the package more

appealing.

6. cups output

Automatically count finished capsules' quantity. It has an online

weigher check function helping reject unqualified products by

itself.

Finished capsules

Package and transportation of the Nespresso coffee capsule filling and sealing rotary machine

1.clean the nespresso coffee capsule filling and sealing rotary

machine and Vegetable oil protect machine not rust

2.Stretch film packaging the nespresso coffee capsule filling and sealing rotary machine

3.Wooden tray to suport the nespresso coffee capsule filling and sealing rotary machine

4.wodden case to protect the nespresso coffee capsule filling and sealing rotary machine